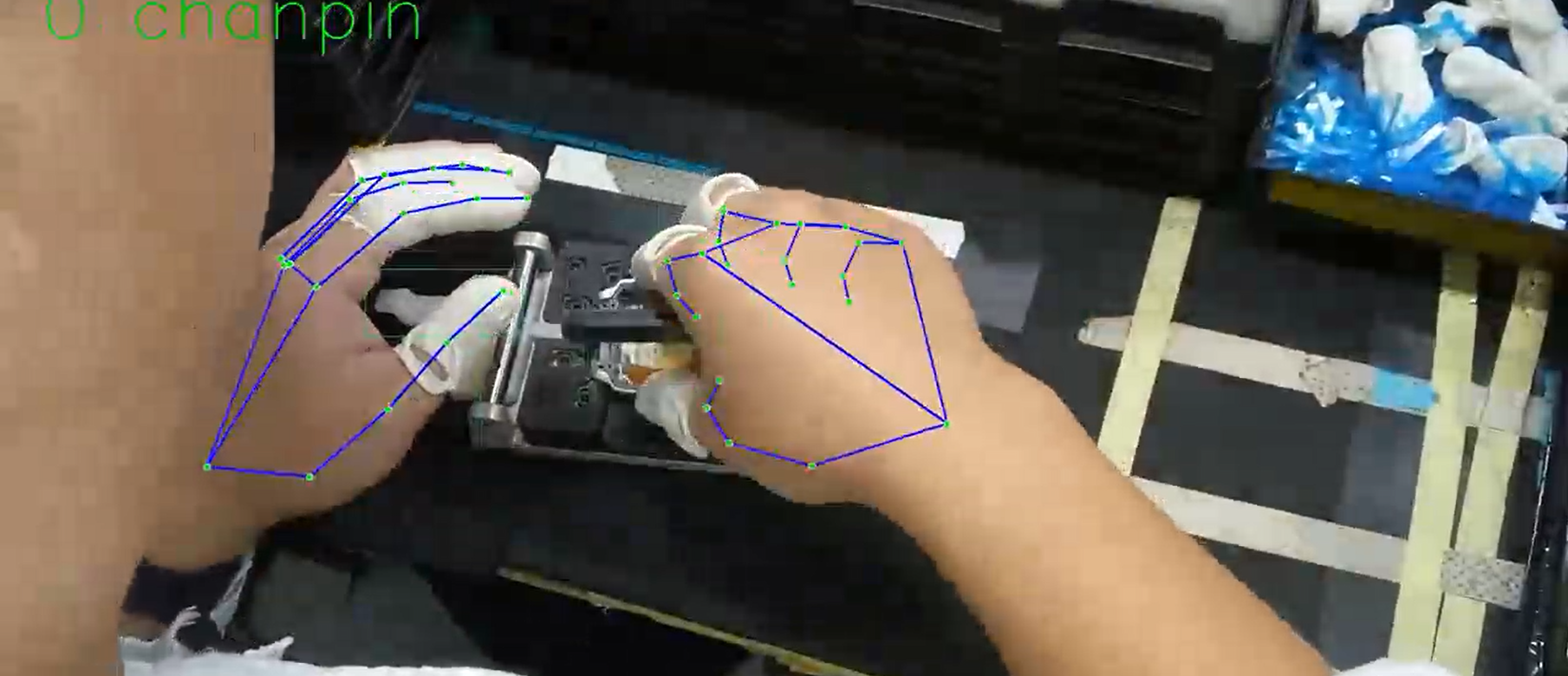

At VIZIFUZE, we harness the power of deep learning and AI-driven visual systems to revolutionize workplace efficiency and safety. Our latest application of AI in action recognition brings an innovative approach to monitoring and optimizing worker movements on production lines. By capturing and analyzing hand and finger joint positions, our system can recognize specific actions and gestures, generating insights and alerts that contribute to a safer, more efficient manufacturing environment.

How It Works

Our AI-powered vision system is designed to track and analyze joint movements in real time. By focusing on the key points of hand and finger joints, we create a virtual model that maps each gesture with precision. This model enables us to identify specific movements and interpret actions, giving us the ability to assess worker posture, gesture accuracy, and overall ergonomics.

Smart Recommendations and Alerts

The advanced AI capabilities allow the system to offer real-time recommendations and alerts. For instance, when a worker’s movement deviates from the ideal posture, such as incorrect finger positioning or overly repetitive actions, the system provides an instant recommendation to correct it. For more critical situations, like hand placement near dangerous machinery or handling tools in unsafe ways, the system issues an alert to both the worker and the supervisor, reducing the risk of accidents and ensuring immediate corrective actions.

Boosting Production Efficiency

The insights generated from our deep learning AI system support ongoing improvements on the production line. By identifying inefficiencies in manual tasks, our system provides feedback that management teams can use to streamline operations. Worker actions are analyzed to determine the most efficient gestures for repetitive tasks, enabling tailored training for workers to adopt these optimized movements. This, in turn, reduces cycle times and increases throughput, directly boosting productivity.

Reducing Costs Through Safety and Precision

Worker safety is a core priority, and reducing incidents has a direct impact on costs. Our gesture recognition system minimizes the risk of injury by actively monitoring high-risk actions and providing instant feedback, lowering accident rates and helping businesses avoid costly downtime and compensation claims. Additionally, by optimizing each task down to precise gestures, the system reduces material wastage and extends equipment lifespan, further lowering operational costs.

A Future of Intelligent Workplaces

The deep learning AI vision system from VIZIFUZE is a step toward the intelligent workplace of the future, where real-time insights lead to smarter, safer, and more cost-effective operations. As we continue to expand the capabilities of our vision systems, we remain committed to delivering solutions that bring tangible benefits to industries worldwide. By increasing both the safety and efficiency of production lines, our technology paves the way for companies to stay competitive and responsive in a fast-paced industrial landscape.

At VIZIFUZE, we believe that advanced technology should empower people, protecting and enhancing the skills of workers while reducing the risks and costs associated with traditional manufacturing environments.