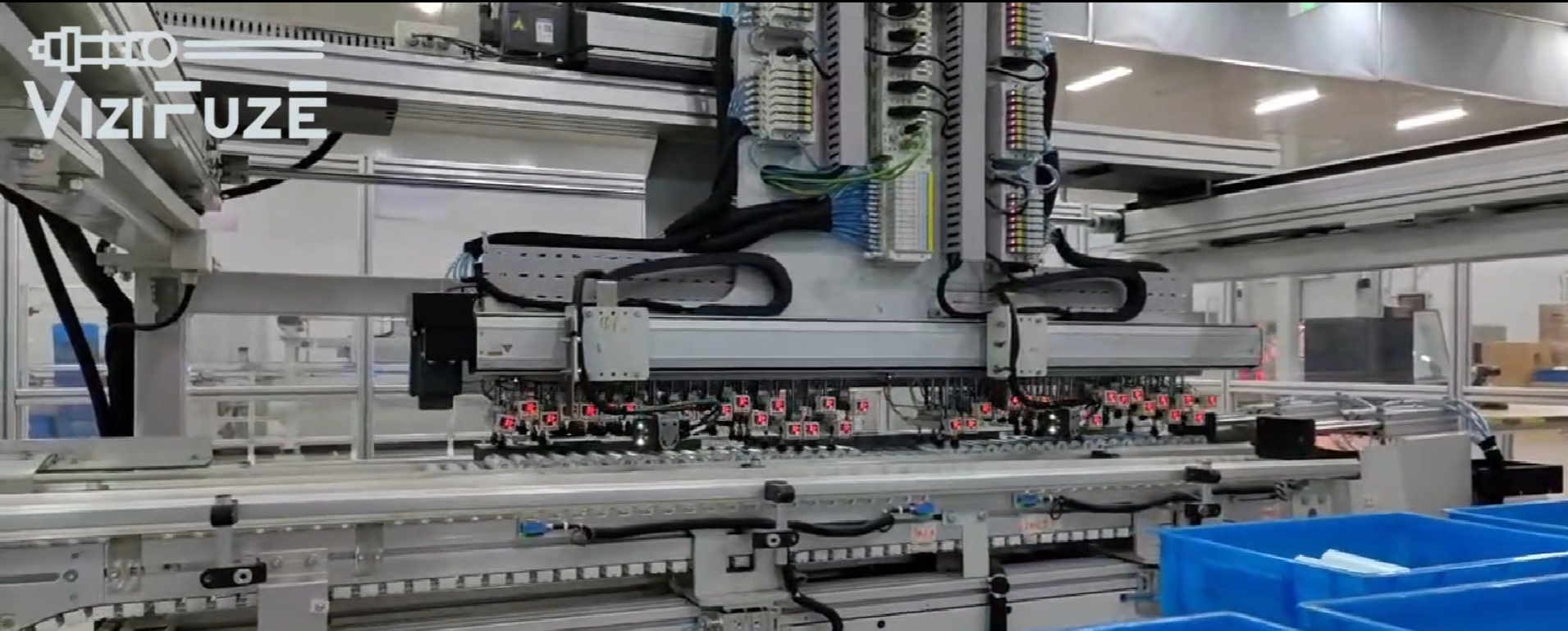

In today’s fast-evolving industrial landscape, precise and high-speed data capture solutions are critical to optimizing production processes. Automotive battery manufacturers face unique challenges that require advanced barcode reading technology capable of handling high-volume production lines, complex code requirements, and strict quality control standards. In a recent project with a leading automotive battery manufacturer, our cutting-edge barcode reading system delivered unmatched performance, meeting the rigorous demands of the industry and gaining the trust of Fortune 500 companies.

Superior Stability and Efficiency for High-Volume Production Lines

Our barcode readers offer unparalleled stability, ensuring uninterrupted performance even in the most demanding environments. In the high-paced world of automotive battery production, where downtime can significantly impact costs and timelines, our solution provides stable, reliable functionality to keep operations running smoothly. Featuring enhanced read efficiency, our readers process barcodes at high speeds with remarkable accuracy, eliminating production bottlenecks and ensuring every battery unit is tracked seamlessly from assembly to final inspection.

With world-class sensors, lenses, and lighting options, our system captures codes under challenging conditions—whether in low-light areas or at unconventional angles—proving its value in environments where traditional barcode scanners fall short. This reliability under varied conditions helps manufacturers maintain strict traceability standards without compromising productivity.

AI-Enhanced Recognition for Complex Code Requirements

In complex battery production settings, accuracy is paramount. Our barcode reading solution is powered by AI-enhanced algorithms that deliver high-level recognition capabilities, ensuring precise, real-time data capture on each unit. This AI-driven recognition adapts to a wide range of code types and conditions, including high-density data, damaged codes, and reflective surfaces commonly found in industrial environments. By leveraging AI, our barcode readers improve process reliability and help detect potential anomalies early, minimizing costly errors and ensuring only the highest quality batteries proceed along the production line.

This level of intelligent scanning is integral to advanced quality assurance protocols, giving manufacturers the confidence that every unit meets the strictest quality criteria.

Configurable Interfaces for Seamless Integration

Our barcode readers come equipped with a diverse range of configurable interfaces, making integration into existing automation systems straightforward. Whether connecting to legacy systems or modern cloud-based platforms, the configurable interface options offer exceptional flexibility and adaptability, accommodating the diverse needs of industrial settings. This ease of integration enables seamless communication between systems, reducing lag and creating a streamlined production flow.

Trusted by Fortune 500 Leaders

The success of our barcode reading technology is underscored by the trust it has gained from Fortune 500 companies. These industry leaders rely on our solution for their critical operations, valuing the stability, accuracy, and efficiency it brings to their production lines. This trust speaks to the consistent, high-performance results our technology delivers in demanding industrial environments, reinforcing our position as a leader in automation and industrial innovation.

Conclusion

In the automotive battery industry, where precision and efficiency are non-negotiable, our advanced barcode reading solution proves indispensable. With AI-enhanced recognition, superior stability, fast and efficient code reading, and the flexibility of configurable interfaces, our system is engineered for optimal performance in complex industrial environments. As industries prioritize accuracy, speed, and scalability, our trusted barcode reading technology stands ready to meet the evolving needs of modern manufacturing and shape the future of industrial automation.